¶ Filament Drying

Just about every 3d printer filament is hygroscopic. That means it absorbs moisture. From the air, in this case. All filaments do it and some do it very quickly. Filament that has absorbed enough moisture to cause problems is referred to as 'wet'.

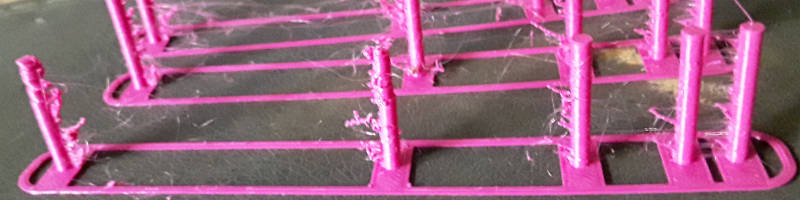

Wet filament causes a lot of problems. In the above photo there's a clear line where part of a print switched over from dry filament to wet. The wet half has a rougher texture, is noticeably thicker (you can feel a fraction of a millimeter rise all around the transition layer), and is most likely weaker as a result. On the inside there was more oozing and supports on the wet portion were much harder to remove. Simply put, wet filament is bad and it should not be underestimated.

PLA takes the longest to absorb moisture. PETg can get wet within a month. Nylon absorbs moisture so readily it's commonly said you should dry it before every print.

¶ Identifying wet filament

Wet filament is pretty easy to identify after you've already printed it. A rough texture is usually a dead giveaway. Any sort of hissing or popping in the nozzle is also a dead giveaway.

Even newly shipped filament is sometimes wet. Unfortunately, unless you weighed it ahead of time, it's very difficult to tell if a spool is wet before printing. For anything pricey it's usually better to dry first and ask questions later.

¶ Filament drying

Commercial filament dryers do exist. An electric (but not gas) oven can also be used for this purpose provided it reliably maintains the correct temperature. That can be a reasonably option for an occasional printer, but a hardcore one will need a dedicated dryer.

A common DIY filament drying solution is to get a $50 food dehydrator and print some walls. Numerous guides and thingiverse files can be found to this end.

¶ Drying

How long you need to dry filament depends on how wet it is. Common dry times vary between overnight to an entire day. You can't really over-dry filament so when in doubt, leave it in. Nylon can absorb so much water that a day is usually considered a minimum--it can take longer.

Drying obviously needs to take place at a temperature below the transition temperature of the filament being dried. The following temperatures are good targets:

| Filament | Temp |

|---|---|

| PLA | 50c |

| ABS | 65c |

| PETg | 65c |

| Nylon | 70c |

| TPU | 55c |

| Dessicant | 65c |

¶ Do I need anything else?

There exist filament enclosures (dryboxes) that keep your filament dry and heated while it's being printed.

If these are useful at all it would be for nylon prints but in practice these do not seem necessary. Keeping nylon filament in an enclosure while it is being printed seems to do well enough.